Six Sigma is used by many companies, local governments, and other institutions. Here are two examples of how Six Sigma improved operational efficiency, saved money, and increased customer satisfaction. Much like a basic quality-control program, Six Sigma quality control works to find and identify areas in need of improvement. Six Sigma provides an answer to the question of what’s the difference between quality assurance (QA) and quality control (QC).

Key Differences Between Lean and Six Sigma

- You don’t need to stick rigidly to the rules of just one project management process.

- Ventura County, California, credited the use of Lean Six Sigma for a savings of $33 million.

- Organisations can differentiate themselves from competitors by consistently delivering high-quality products and services.

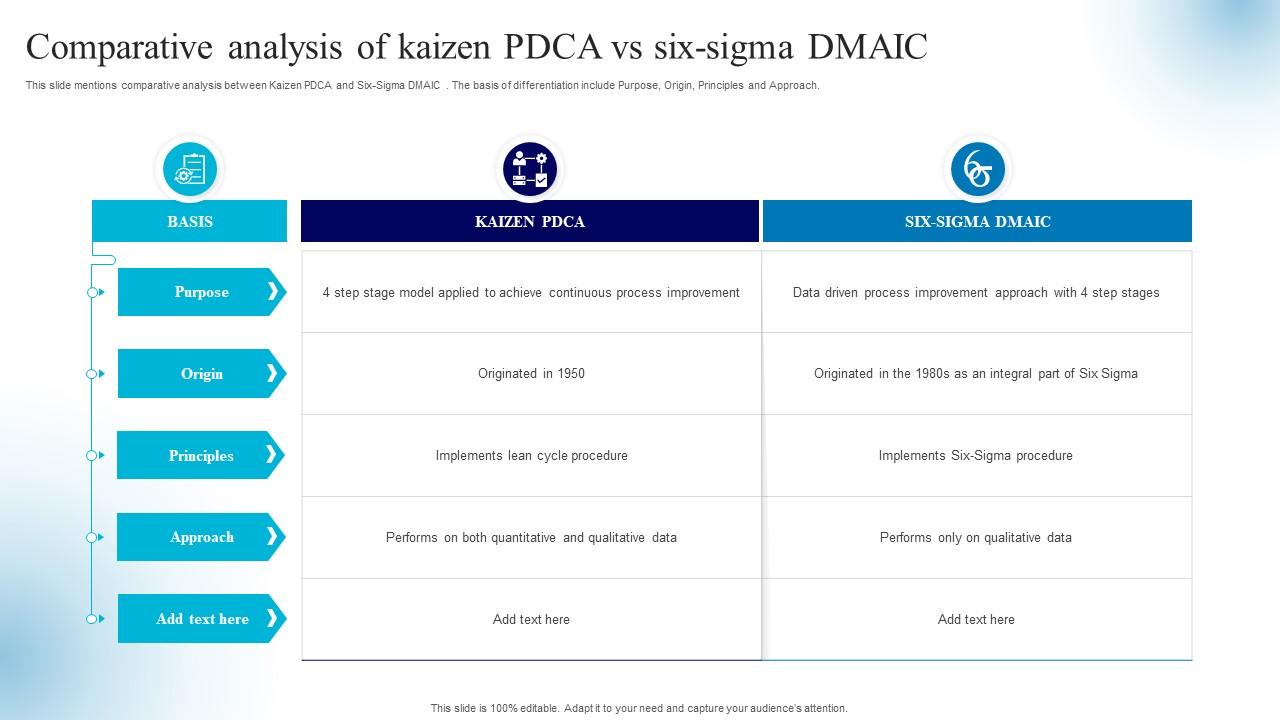

- Lean looks to maximize value for the customer with the smallest number of resources, whereas Six Sigma aims to achieve high customer satisfaction by minimizing costs.

This culture of continuous improvement becomes ingrained in the organisation’s DNA, leading to a mindset where everyone is focused on driving positive change. To commence the Six Sigma journey, organizations must first understand the methodology’s fundamentals and establish a robust infrastructure for its implementation. This involves setting clear objectives, acquiring the necessary resources, and fostering a culture of data-driven decision-making. Lean looks to maximize value for the customer with the smallest number of resources, whereas Six Sigma aims to achieve high customer satisfaction by minimizing costs. Both methods can easily eliminate waste and improve efficiency, but they do so in different ways.

Lean Cons

It is especially relevant for business leaders, project managers, quality control professionals, and anyone seeking to enhance operational efficiency and customer satisfaction. In today’s competitive marketplace, quality is a crucial and distinguishing attribute in products and services. Lean Six sigma green belt certification is one of the most popular certifications among lean six sigma certification.

Implementation challenges

Anyone who wishes to learn it can take courses that lead to various levels of certification. Ventura County, California, credited the use of Lean Six Sigma for a savings of $33 million. The county government began to use the program in 2008 and has trained more than 5,000 employees in the methodology.

Lean Six Sigma: Combining the Best of Both Worlds

According to a report released by General Electric, their company was able to save more than $8 billion thanks to identifying and eliminating such defects. Motorola Company, further improved the six sigma methodology and gradually elevated optimization in its processes. The company spread and introduced the practical six sigma methodology to the world. In this phase, Motorola introduced a terminology “Digital Six Sigma”, which included a business wide ‘Balanced Score card’ to measure the success of the system. Here the basic focus of Motorola Company was to identify the root cause of many problematic areas that were inherently complicated and risky.

Upcoming Business Improvement Resources Batches & Dates

One of our training experts will be in touch shortly to go over your training requirements. The structured nature of Six Sigma can sometimes limit flexibility in responding to rapidly changing business environments. Organisations need to strike a balance between standardisation and the ability to adapt to evolving market conditions. Six Sigma often relies on the expertise of trained professionals known as Black Belts and Green Belts.

An incorrect or half-baked implementation of Six Sigma can do more harm than not implementing it at all. Large amounts of data were collected on a daily and weekly basis from various servers. The incidents were prioritized based on how severely the defects affected the business and the company’s underlying services. Data analysis and reporting identified the specific defects, after which remediation steps for each defect were established. Employees of all levels must be trained in the various positions of the methodology as well. In the quest to refine processes and eliminate waste, Six Sigma may limit flexibility for unique circumstances, and leave less room for innovative new tools or methods.

Lean Six Sigma uses an approach that focuses on hybridizing these two aspects, but unfortunately, requires deeper data assessment to compare operations and their outcomes. Learn about the Advantages & Disadvantages of Six Sigma in our comprehensive blog. Discover how Six Sigma methodologies can enhance efficiency, quality, and customer satisfaction while also understanding the potential challenges and limitations it may pose to your organisation. Gain valuable insights to make informed decisions about implementing Six Sigma in your business. Originating from Motorola in the 1980s, Six Sigma was initially developed as a quality control methodology. Later, General Electric widely embraced and promoted Six Sigma, further popularizing its principles across various industries worldwide.

By diligently adhering to its principles and leveraging data-driven strategies, businesses can significantly minimize defects, improve customer satisfaction, and achieve sustainable competitive advantages. Since Motorola’s introduction in 1986, it has also been widely used as a quality measure that seeks near elimination of defects by employing statistical methods. The measurements adopted are founded on process strategies highlighting variation reduction, which theoretically, triggered improvements in the actual process. Motorola’s new business strategy of adopting Six Sigma was received with mixed reactions back in 1986. While some saw it as a revolutionary strategy that would significantly improve efficiency, others dismissed it as a complicated process that wouldn’t lead to improved profits. Six Sigma practitioners use statistics, financial analysis, and project management to identify and reduce defects and errors, minimize variation, and increase quality and efficiency.

It has since spread, not only to a number of business disciplines, but also to a large number of organizations and industries. Many, in fact, have adopted it formally as their primary means of quality control and business process high low method calculate variable cost per unit and fixed cost improvement. Below, we will look in more detail at this methodology, its benefits, its drawbacks, and its alternatives. Understanding the advantages and disadvantages of Six Sigma is essential to use it effectively.

From registration fees to course materials, from dedicated trainers to potential travel expenses, the financial aspects can pile up. Moreover, it isn’t just about money; it’s about the hours, days, and sometimes even months that employees invest in the training. The prolonged nature of this training means a substantial amount of time away from regular work.